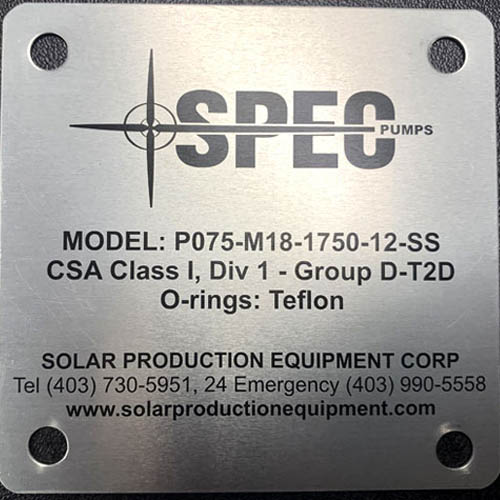

Anodizing is a process that results in long term durability for indoor usage (30 - 50 years) and approximately 10 years durability for outdoor usage, depending upon environmental conditions. Ideal applications for the anodizing process include asset and equipment labels such as valve plates, identification plates, warning plates, and caution plates.

The anodizing process starts with specially treated aluminum plates. Images are dyed into the pores of the metal using a process much like screen printing. Once dry, the plates are chemically treated to initiate the anodizing process. This results in a glass-clear, sapphire-hard, subsurface anodized layer on the top. The end result is an incredibly abrasion resistant product with super sharp graphics.